- Normal dosage: 0.1% ∼ 1.0% ( BWOC ). It is more efficient if it is used combining with USZ friction reducing additive when middle-deep well is cemented, It can reduce the consistency of cement slurry and improve the rheology.

- It can reduce the consistency of cement slurry and improve the rheology.

- Retard the thickening time efficiently.

- Generally used in oil wells whose circulate temperature under bore is below 230℉.

- Mixed without water.

Middle Temperature Retarder for Oil Well Cement

Product Description :

GH-I can stick on the surfaces of cement hydrate to inhibit contacting between cement and water, also stick on the surfaces of crystal nucleons to prevent their enlarging. So it can retard hydrating of cement slurry.

Performance Characteristics :

Technical indicators :

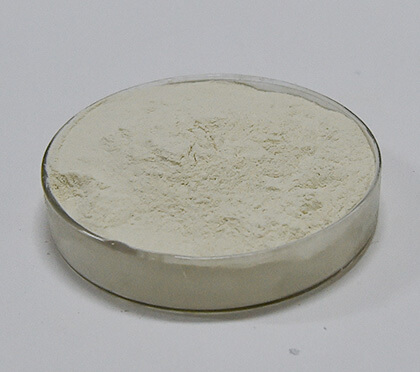

| Appearance | Pale yellow powder |

| Initial consistency, Bc | ≤ 30.0 |

| Thickening time / 176℉, 46.5MPa, 45min | Adjustable |

| Compression strength, MPa / 215.6℉, 21MPa, 24h | ≥ 14.0 |

| The ingredients of the cement slurry in the table are: G class cement, W/C 0.44, Dosage of GH-I: 0.1% ∼ 1.0% + USZ: 0.4%, Water quality: distilled water. | |

Packaging, storage and transportation :

- Be packed in three-layer plastics bags with 25kg per bag.

- Be kept away from moisture and possible damage of the packages during transportation, to be stored in cool and dry situation.

- Storage life time is two years.